The Mosi project came to a halt as I devoted almost all my spare time to getting the SWIFT flying. Right now, I'm in the midst of adapting a small 4-stroke power unit to the SWIFT undercarriage. The engine I have selected is based on the single cylinder 212cc "Predator" engine.. you can buy one from Harbor Freight for $100. It's "Made in China", and while that usually means dicey quality, this is actually a solid-built engine. I've stripped it, added some performance parts, replaced gaskets, and am now planning to mill the heads and bore/replace the carb... I'm hoping to get 14 hp @ 5,000 RPM out of it. Dan Batchelor has done a lot with this engine and he's been very helpful and encouraging. He reports on his continuing progress on the "Egg Motor" Yahoo group site, so check it out if you're interested.. it's primarily a place for 4-stroke direct-drive paramotor "egg-sperimenters".. ;) http://uk.groups.yahoo.com/group/eggmotor/

The Mosi project came to a halt as I devoted almost all my spare time to getting the SWIFT flying. Right now, I'm in the midst of adapting a small 4-stroke power unit to the SWIFT undercarriage. The engine I have selected is based on the single cylinder 212cc "Predator" engine.. you can buy one from Harbor Freight for $100. It's "Made in China", and while that usually means dicey quality, this is actually a solid-built engine. I've stripped it, added some performance parts, replaced gaskets, and am now planning to mill the heads and bore/replace the carb... I'm hoping to get 14 hp @ 5,000 RPM out of it. Dan Batchelor has done a lot with this engine and he's been very helpful and encouraging. He reports on his continuing progress on the "Egg Motor" Yahoo group site, so check it out if you're interested.. it's primarily a place for 4-stroke direct-drive paramotor "egg-sperimenters".. ;) http://uk.groups.yahoo.com/group/eggmotor/But I have NOT abandoned the Mosi project!! ... just temporarily neglected it. I have gone back and forth on Mosi engine and landing gear options until I'm dizzy, but I'm committed now to the original plan of using the 4A032 engine. The more powerful 2A042 turned out to be just a bit too heavy and wide.. sticking out of the cowling several inches on each side.. which is kind of ugly for my taste, and is a significant drag increase that would erode power-off soaring performance... the 4A032 just fits inside the cowling. Also contributing to my re-reversal of engine selection are some encouraging reports of performance upgrades that others have successfully made to 4A032 engines. In fact, there's reportedly a MiniMax ultralight out there powered by a souped-up 4A032 that has "hundreds of hours" on it and still running strong and smooth. Upgrades typically include a larger carb and milled heads for higher compression. I may install an electronic fuel injection system and new ignition from Ecotrons.. expensive, but more reliable, easier starting, automatically altitude-compensating, and free of carb icing problems.

The Mosi landing gear will be taildragger style, like I had originally envisioned.. it looks cooler than tricycle gear, plus has lower drag and is easier to connect up with existing hardware. I obtained Grover spring aluminum legs for the mains.. this has a fairly low drag profile, and provides an extra 3 inches of prop clearance compared to the stock monowheel configuration. That'll be perfect for the 40-inch diameter prop that is matched to the 4A032.

So, during 2011-2012, I admittedly didn't accomplish much on the Mosi project... guilty as charged.

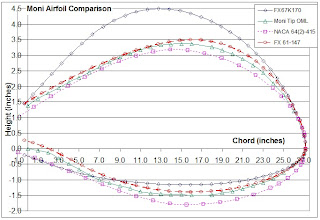

However, in the last couple of months, the project has started moving again. The molds for the wing tip extensions were cut on my CNC foam cutter out of huge blanks of 3 lb./cu.ft. EPS foam, seen here. These wings tips add 4 feet to the span on each side and taper from 26.5 to 9.5 inches in chord, not counting ailerons. Added to that will be non-movable wingtips, shaped similar to "Horner" tips.. That will bring the total wingspan of the Mosi to 34.5 feet. I also carefully measured wing airfoil co-ordinates for a good fit to the metal wings and found out that the original Moni airfoil section is a very close fit to Wortmann's FX 61-147, contrary to other reports.

Also cut were the foam molds for the Y-tail airfoils.. I decided to go with the old standby tailplane airfoil, NACA 0012. The Eppler airfoil I had originally planned on using is a laminar section, which is a little trickier to implement, plus the tail surfaces are mostly in turbulent prop wash anyway, so the primary benefit of a laminar flow section is lost.

More updates coming soon.

Dan